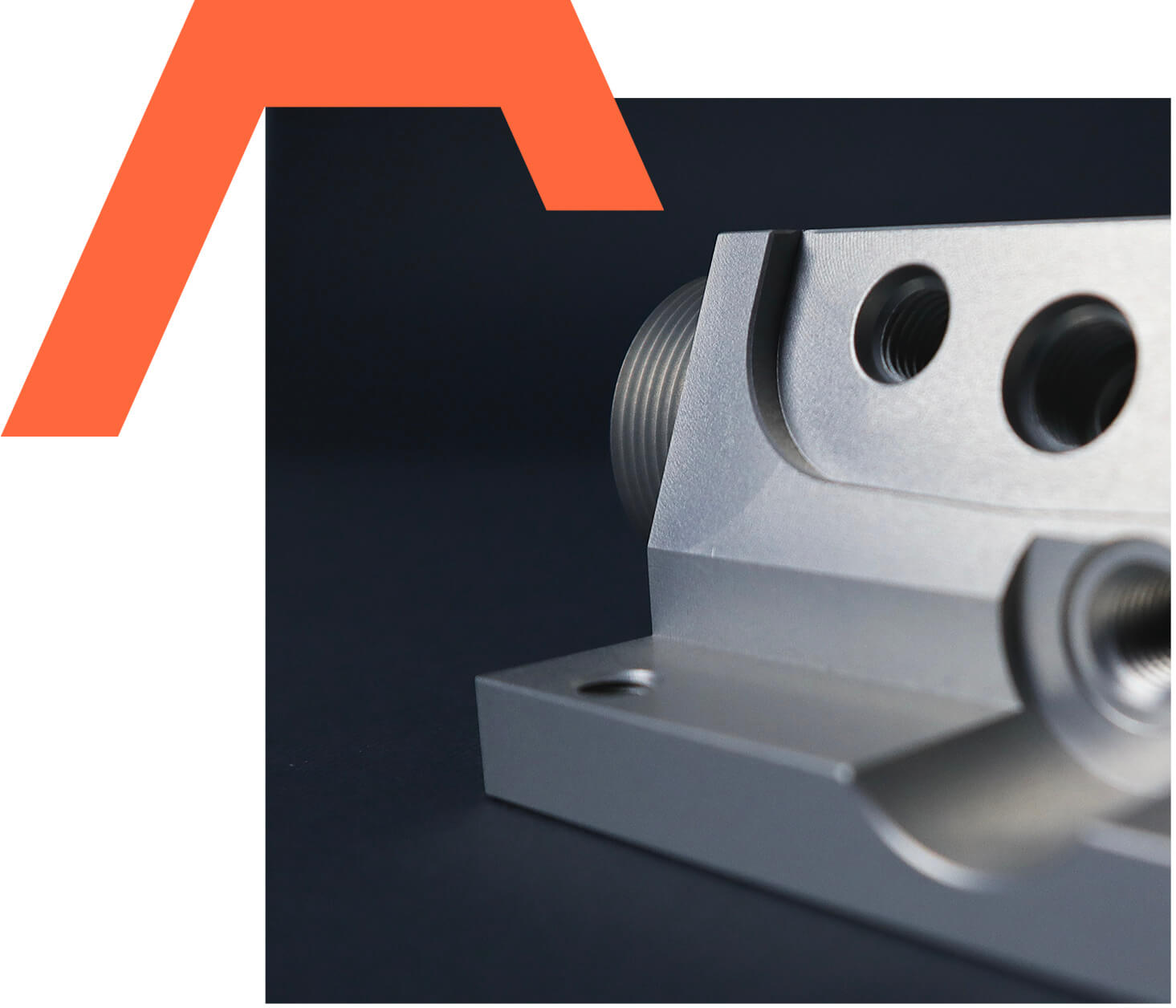

ANODISING FACILITY FOR PRECISION PARTS

We have been handling aluminum processing and anodising orders for 40 years. We offer a wide range of services (including technical anodising, decorative anodising, and aluminum coloring), free quotes, and quick turnaround time.

The full spectrum of services

OUR OFFER

Used to protect the surface of the part from corrosion and, additionally, to give it an aesthetic appearance. The formed layer possesses higher mechanical and chemical resistance.

Clear anodising

Clear (transparent) anodising services that provide high resistance to corrosion and tarnishing.

Color anodising

Color anodising services for decorative elements using organic pigments made in SANDALOR® technology.

Black anodising

Aluminium blackening services for parts exposed to stronger corrosive factors.

A FEW WORDS ABOUT US

Professional aluminum anodising services

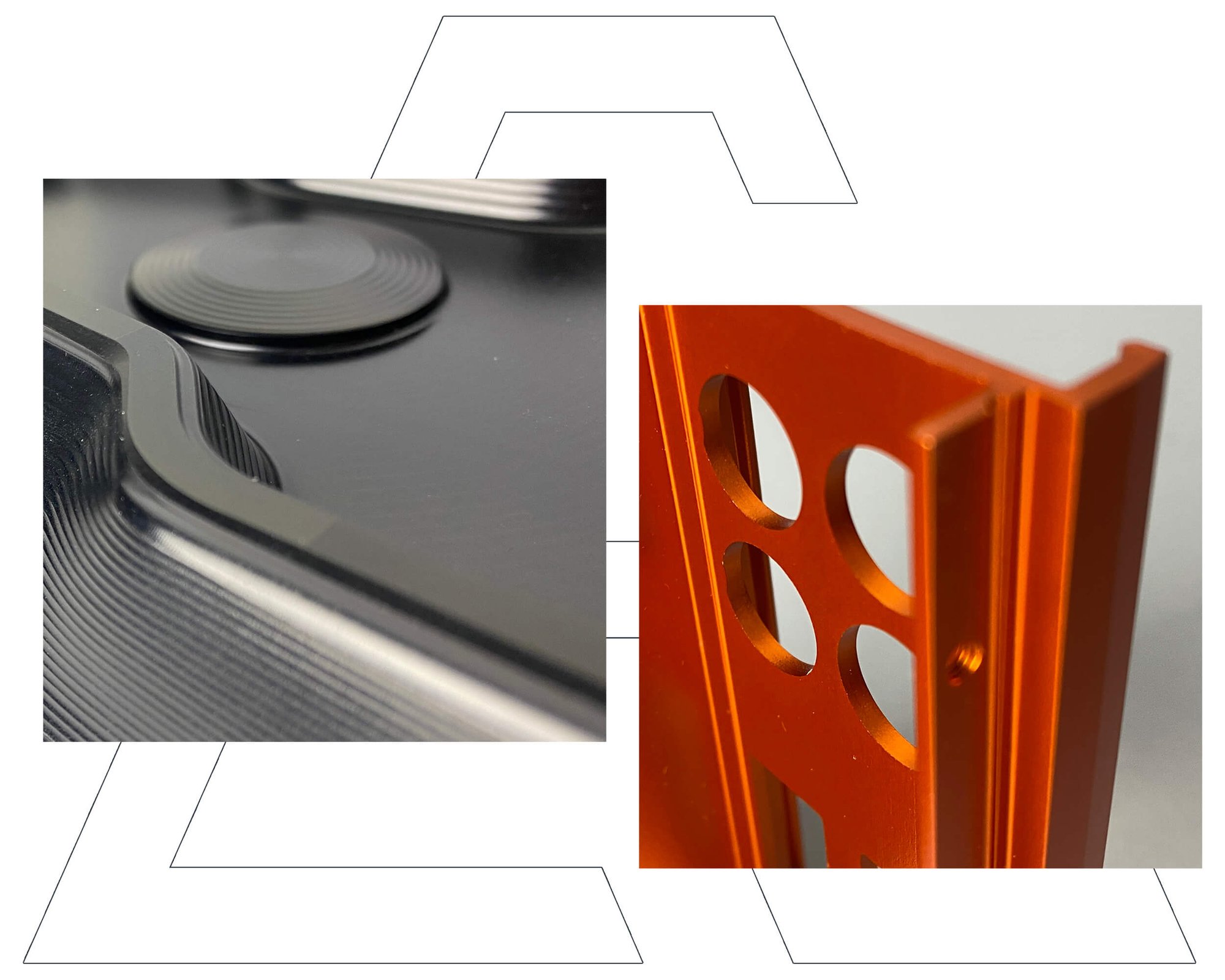

The Precision Parts Anodising Facility was established in 2023 as a collaboration between the professional RADMOT CNC Turning and Milling (40 years in the industry) and Eloxal Zwickau (more than 10 years of experience in aluminum anodising).

Both companies feature in their portfolio the production of parts for the automotive, electrotechnical, medical, machinery, and many other industries. With the combination of knowledge and experience, we at A.C.P. offer services of the highest quality, and our work focuses on precision and meeting the needs of our Customers.

Our offer

ADDITIONAL SERVICES

We also include in our offer surface treatment of parts.

Glass bead blasting of parts

Blasting treatment to clean and make the surface of the part smooth and uniform.

Chemical polishing of parts

Removes imperfections by giving a shine through the use of chemical processes.

Electrochemical polishing of parts

Cleans, smooths and gives a high gloss using electricity and electrolyte.

Anodising services

We provide

- keeping tight tolerances

- top quality aesthetics (uniform color and thickness of the anodised layer)

- safe internal logistics of parts (no bumps, scratches, damage)

- short lead times and on-time deliveries

Why us

Benefits of anodising at ACP

- anodising of precision parts (800 mm x 600 mm x 1000 mm galvanizing pots),

- service of experienced operators and specialists (40 years in the CNC processing market and 10 in the aluminum anodising market)

- comfort, timely handling of orders, and secure logistics (the entire production process can be carried out in one place)

PRECISION PARTS ANODISING

The entire process of manufacturing and anodising aluminum parts in one place

By conducting the entire process of manufacturing and anodising aluminum parts in one

facility, we ensure the highest quality workmanship and timely completion of orders. Contact

us and see how our professionalism can translate into your savings and profits.